Handheld Laser Welding Equipment

Joylaser laser's handheld continuous laser welding machine is welding machine is widely used in many industries ,such as kitchen, household appliances, advertising, molds, stainless steel doors and widows ,handicrafts, household products, furniture, auto parts and so on.

The working mode of the handheld fiber laser welding machine is simple, hand-held welding, flexible and convenient, and the welding distance is longer.

The operation is simple, and you can work without a work permit. The weld seam is smooth and beautiful, which can reduce the subsequent grinding process, saving time and cost. The advantages of fast welding speed and no consumables. Laser welding is fast, 2-10 times faster than traditional welding, and one machine can save at least two welders a year. Welding of metal materials such as thin stainless steel plates, iron plates, galvanized plates, etc., can perfectly replace traditional argon arc welding, electric welding and other processes.

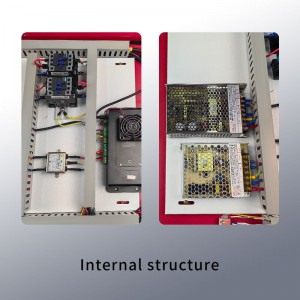

Each Part Function as below:

1: Touch Screen

Change the welding parameters via the touch screen control panel. The user could save the normal using parameter inside the system, and fast setting it before work.

2:Auto Wire Feeder

Our wire feeding system support max 3.0mm diameter metal wire, and with the double motor inside the machine case, which give the more stable support for the machine working.

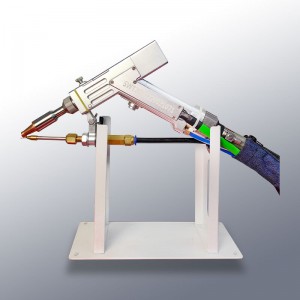

3: Nozzle and Lens

Customized special nozzle for meet different work. Help use get the better welding effect. Whole machine very easy to learn, one person only need 10 minutes to become the skilled worker.

4: Laser Head

Handheld light Laser Welding head, only with 800g weight, which makes operator work more longer time per day. There have double protective lens, and the Temperature Sensor inside the laser head, which give the biggest protection.

5:Safety Clip

There have the red safety clip on the side of the laser head. The operator must fix the clip on the metal materials, then the machine could normal working. This is the protection for the operator, which give the more safe working environment.

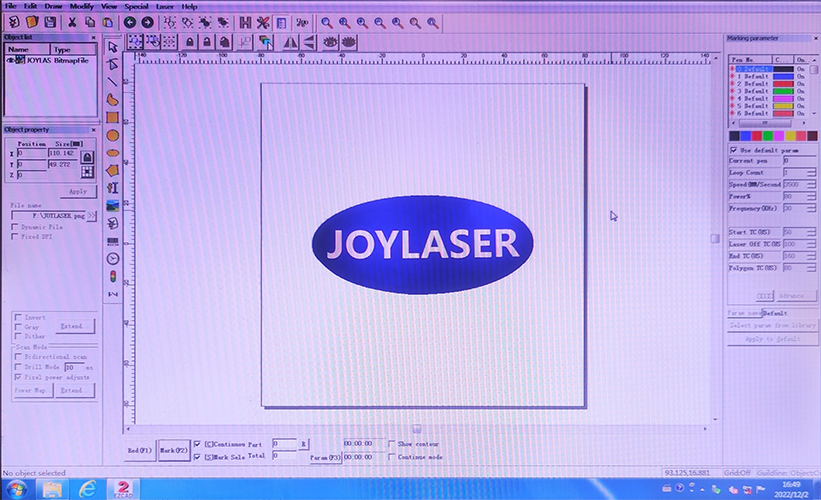

✧ Operation Interface

The software of JOYLASER marking machine needs to be used in conjunction with the hardware of the laser marking control card.

It supports various mainstream computer operating systems, multiple languages, and software secondary development.

It also supports common bar code and QR code , Code 39, Codabar, EAN, UPC, DATAMATRIX, QR CODE, etc.

There are also powerful graphics, bitmaps, vector maps, and text drawing and editing operations can also draw their own patterns.

✧ Technical Parameter

| Equipment model | JZ-SC-1000W JZ-SC-1500W JZ-SC-2000W |

| Laser type | HANDHELD LASER WELDING MACHINE |

| Laser wavelength | 1064nm |

| Laser frequency | 1-100KHz |

| Motion mode | continuity |

| Light output mode | QCW/CW |

| Pulse width | 0.1-20Ms |

| Solder joint point size | 0.2-3.0mm |

| Power demond | 380v±5v 50-60 Hz/220v±5v 50-60 Hz/ |

| Cooling mode | Water cooling |

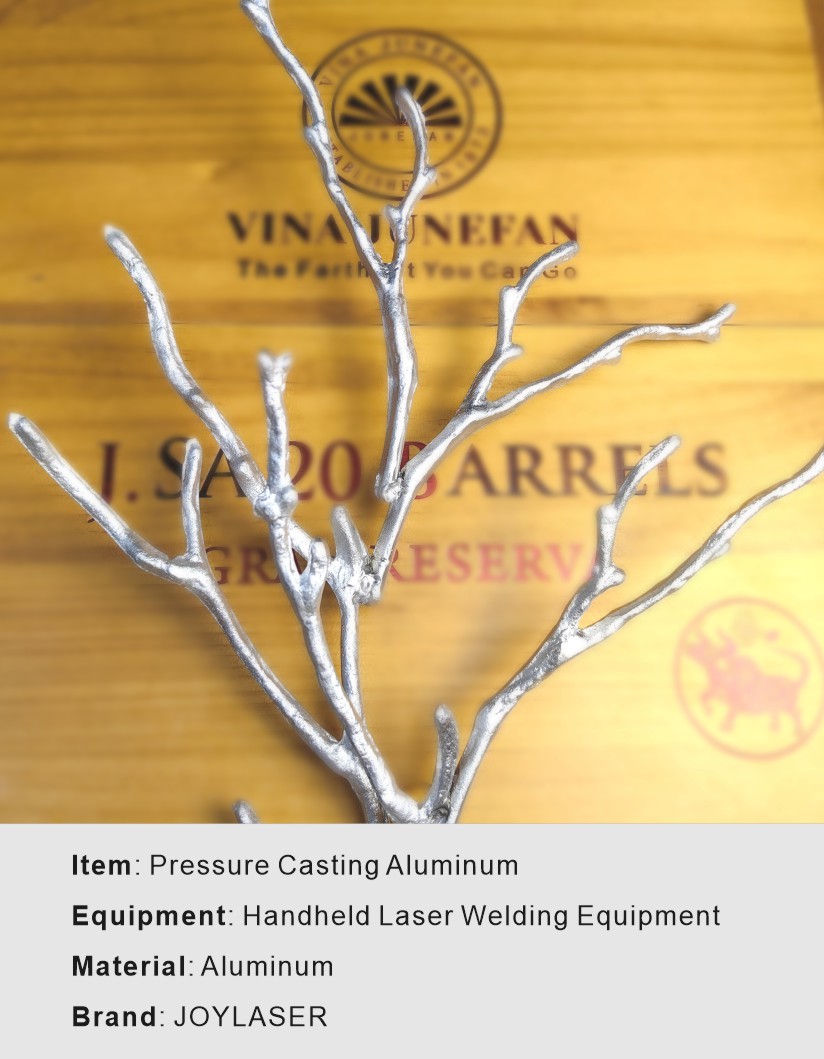

✧ Sample Of Product