Industrial Ultraviolet Vision Marking Machine

✧ Machine Features

CCD visual laser marking machine uses the principle of visual positioning. First, the template of the product is formulated, the product shape is determined, and the product is saved as a standard template. During normal processing, the product to be processed is photographed. The computer quickly compares the template for comparison and positioning. After adjustment, the product can be accurately processed. It is applicable to situations such as heavy workload, difficult feeding and positioning, simplified procedures, workpiece diversity and complex surfaces. It is widely used in various industries. Cooperate with the assembly line to realize automatic laser marking. This equipment is equipped with automatic photoelectric induction and marking of processed products following objects in the process of moving along the assembly line. No manual positioning operation is required to achieve zero time marking operation, which saves the process of special laser marking. It has high efficiency, high precision, safety and reliability and other high performance characteristics. Its production capacity is several times that of ordinary marking machines, greatly improving work efficiency and saving labor costs. It is a cost-effective supporting equipment for laser marking operations on the assembly line.

✧ Application Advantages

The intelligent visual positioning laser marking machine aims at the problems of difficult material supply, poor positioning and slow speed caused by the difficulties in fixture design and manufacturing in batch irregular marking. The CCD camera marking is solved by using an external camera to capture the feature points in real time. The system supplies materials and concentrates at will. The positioning and marking can greatly improve the marking efficiency.

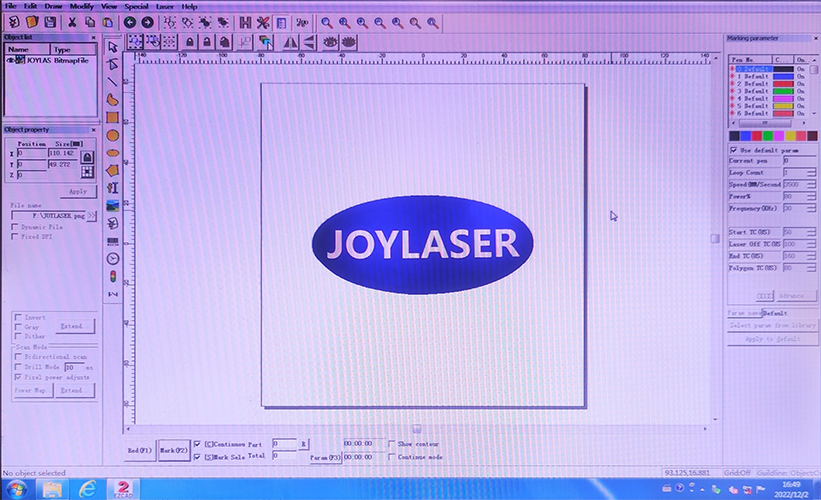

✧ Operation Interface

The software of JOYLASER marking machine needs to be used in conjunction with the hardware of the laser marking control card.

It supports various mainstream computer operating systems, multiple languages, and software secondary development.

It also supports common bar code and QR code , Code 39, Codabar, EAN, UPC, DATAMATRIX, QR CODE, etc.

There are also powerful graphics, bitmaps, vector maps, and text drawing and editing operations can also draw their own patterns.

✧ Technical Parameter

| Equipment model | JZ-CCD-Fiber JZ-CCD-UV JZ-CCD-CO2 |

| Laser type Fiber laser | UV laser RF Co2 laser |

| Laser wavelength | 1064nm 355nm 10640nm |

| Positioning system | CCD |

| Visual range | 150x120 (depending on the material) |

| Camera pixels (optional) | 10 million |

| Positioning accuracy | ± 0.02mm |

| Pulse width range | 200ns 1-30ns |

| Laser frequency | 1-1000KHz 20-150KHz 1-20KHz |

| Carving line speed | ≤ 7000mm/s |

| Minimum line width | 0.03mm |

| Positioning response time | 200ms |

| Power demand | AC220V 50Hz/60Hz |

| Power demand | 5-40A ℃ 35% - 80% RH |

| Cooling mode | air-cooled cold air cooled |